A foundry, combined with extensive in-house mechanical processing capabilities, is what sets us apart as a company. This allows us to maximize the cost-benefit ratio for our customers while significantly reducing risks.

Every purchaser responsible for sourcing cast parts should be familiar with the following scenario: A cast part is ordered from a foundry, and the mechanical processing is outsourced to a subcontractor.

During processing, the subcontractor discovers defects in the casting but still expects to be paid for their services.

The foundry denies responsibility and refuses to cover the additional costs. These situations can pose a challenge for buyers, especially when components are urgently needed for critical projects... With us, this risk does not exist!

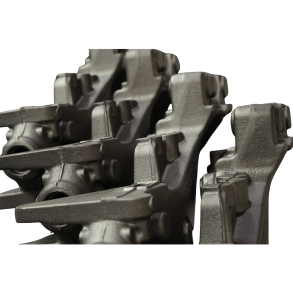

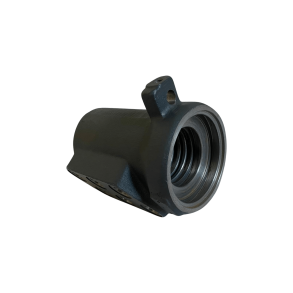

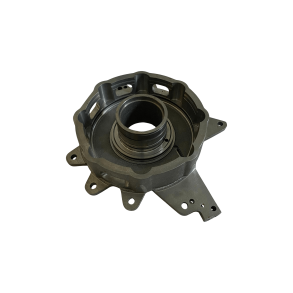

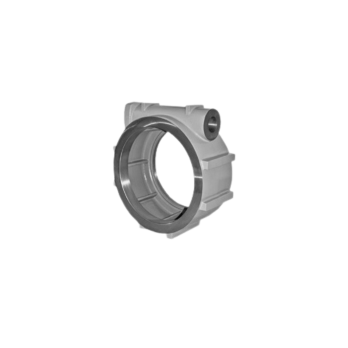

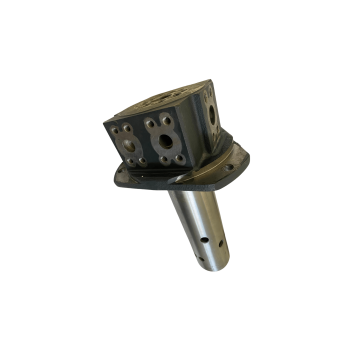

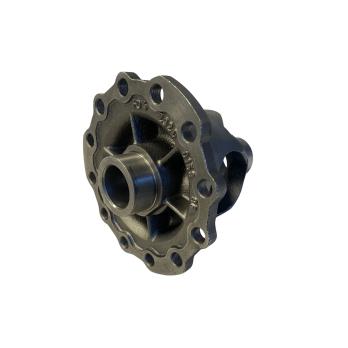

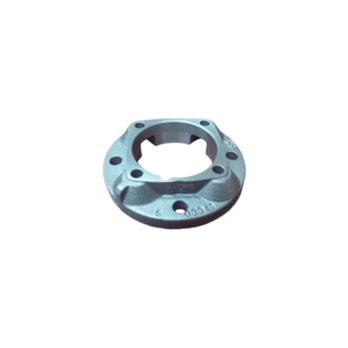

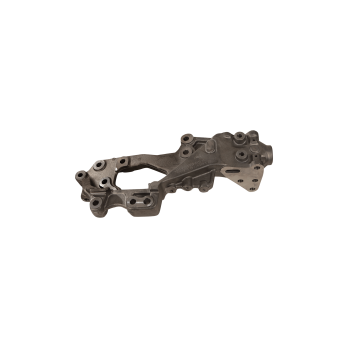

We cast and machine all common and specific materials such as grey cast iron, spheroidal graphite iron, aluminum, bronze, steel, and stainless steel alloys in various dimensions and quantities. Depending on customer requirements, machined cast parts can be delivered with optional coatings and/or paint finishes.

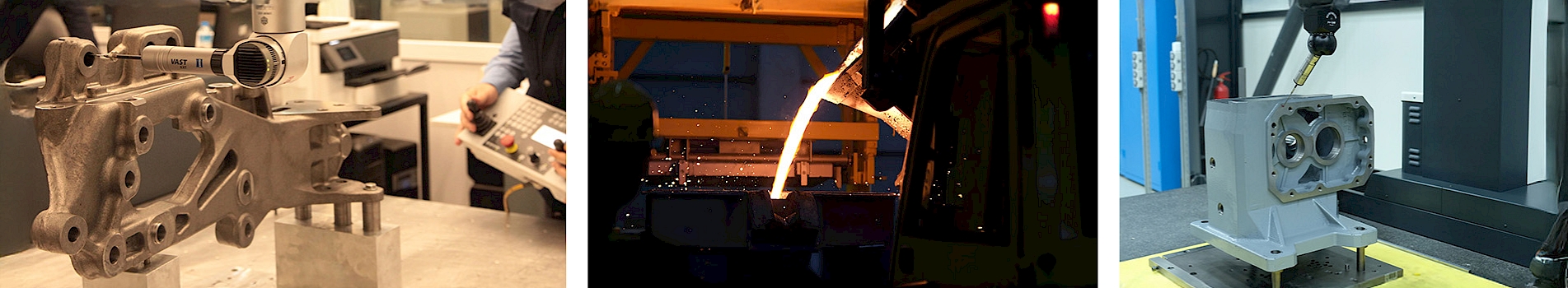

For the production and quality control of our components, we rely exclusively on the latest technologies and processes. Our expertise, derived from many years of experience, and our high level of in-house manufacturing make us one of the leading companies in the field of cast part production.

Additional manufacturing processes such as electrical discharge machining (EDM), grinding, coating, various heat treatments, and painting are also carried out in-house. All components we produce can be manufactured independently of external parties. We define the manufacturing processes ourselves and carry them out according to our internal guidelines, which allows us to ensure the quality of our cast parts and the manufacturing processes we perform.

Cast parts represent an essential product category of our company. Our passion for metallurgy and our exceptionally high level of in-house production distinguish us from alternative foundries in the mechanical engineering industry. Manufacturing the most complex and highly precise cast parts is part of our daily business. Cavities in castings or complex order processing? Not here! Blanks and finished products are manufactured under the same roof—sleepless nights for buyers and project managers are a thing of the past!

Grey Cast Iron Parts

Tonnage – maximum: 1,000 kg per component

Ductile Cast Iron Parts

Tonnage – maximum: 500 kg per component

Steel Cast Parts

Tonnage – maximum: 1,000 kg per component

Stainless Steel Cast Parts

Tonnage – maximum: 1,000 kg per component

Aluminum Cast Parts

Tonnage – maximum: 500 kg per component

Bronze Cast Parts

Tonnage – maximum: 20,000 kg per component

Revenue Volume

The revenue generated by the sale of cast parts by the Alform Group amounts to 12 million euros per year – approximately 15% of the total annual revenue.

Environmental Protection

According to a calculation we conducted, the production of our cast parts emits approximately 17% less greenhouse gases compared to regular production facilities in the mechanical engineering sector.