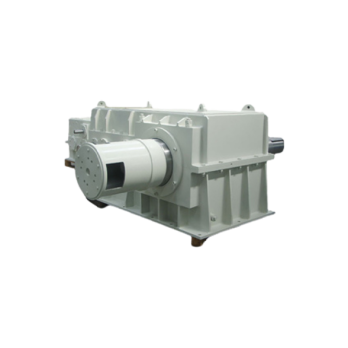

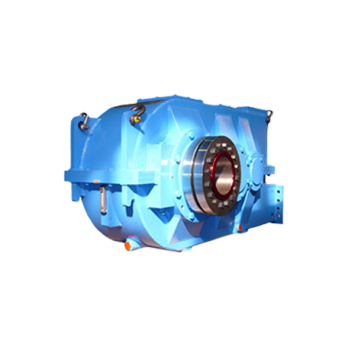

Our custom gearboxes are used across various industries and companies worldwide. Thanks to our extensive range of machinery and years of experience, we are capable of manufacturing both highly complex and simpler custom gearboxes in variable quantities and dimensions very cost-effectively.

All components of our custom gearboxes can be internally manufactured due to our high degree of in-house production—from spiral bevel gears and toothed parts to cast housings, welded housings, or turned parts. This minimizes risk, keeps delivery times short, and maximizes cost-effectiveness, giving our customers a significant competitive advantage by sourcing the entire custom gearbox from one source.

Our service range in project execution includes the design and construction of custom gearboxes for our customers, along with the support of our specialists in designing and creating production drawings. We actively engage in the development process of your projects to offer optimized products and cost-saving potentials.

For over 50 years, we have been producing custom gearboxes, establishing ourselves as a leading company in gearbox technology. We can grind the toothed parts of our gearboxes to ensure tooth quality up to AGMA 12, routinely and without complications.

Additional manufacturing processes such as EDM machining, coating, various heat treatments, and painting are also carried out internally. We can manufacture all components independently of external parties and determine manufacturing processes according to our internal guidelines to ensure the quality of the components used in our custom gearboxes and the manufacturing processes.

Custom gearboxes are an essential product category in our company. These are used in highly complex constructions and mechanisms, necessitating consistent and reliable product quality. Our passion for precision and attention to detail, combined with our high degree of manufacturing depth, enable us to meet the demands of our customers. We make the seemingly impossible possible and make it our daily mission to meet your requirements and goals. From design to manufacturing, we are here to deliver an optimized, cost-effective, and high-quality gearbox solution.

Torque of our custom gearboxes

Up to 10,000,000 Nm

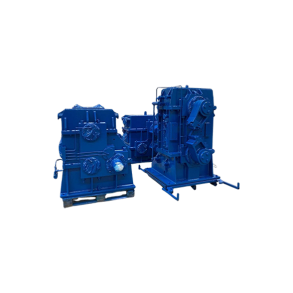

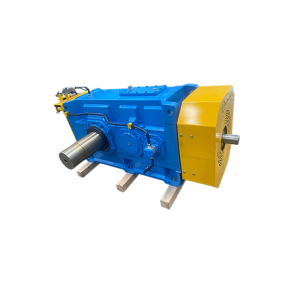

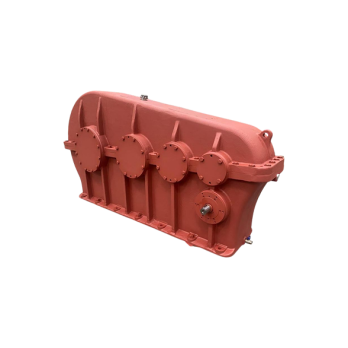

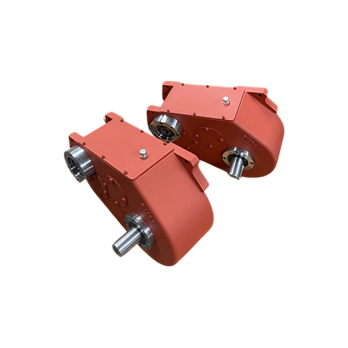

Types of custom gearboxes we manufacture

- Parallel shaft helical gearboxes – Power range: 1 – 5,000 kW

- Planetary gearboxes – Power range: 1 – 2,500 kW

- Bevel gearboxes – Power range: 1 – 5,000 kW

- Worm gearboxes – Power range: 0.1 – 110 kW

- Wind turbine gearboxes – Power range: 1 – 2,500 kW

Types of internally manufactured toothed parts used in our custom gearboxes

- Spur gears

- Straight bevel gear sets

- Spiral bevel gear sets

- Worm gear sets

- Toothed shafts

Revenue Volume

The revenue generated by the sale of special gearboxes by the Alform Group amounts to 6 million euros per year.

Environmental Protection

According to a calculation we conducted, the production of our special gearboxes emits approximately 5% less greenhouse gases compared to regular production facilities in the mechanical engineering sector.