Our company specializes in the manufacturing of aluminum die-cast parts and zinc die-cast parts, complemented by comprehensive mechanical machining capabilities. This proven combination allows us to maximize cost-effectiveness for our customers without compromising on quality. With years of experience and a clear commitment to excellence, we are a trusted partner in the industry.

Our broad range of services includes customized production and precise machining of aluminum die-cast parts and zinc die-cast parts in various dimensions and quantities. Additionally, we offer the option to coat or paint mechanically machined aluminum and zinc die-cast parts according to specific customer requirements. As part of our order processing, we are also pleased to assist in the design or optimization of these components to maximize their benefits or cost-effectiveness. Our skilled designers are available to provide expert guidance.

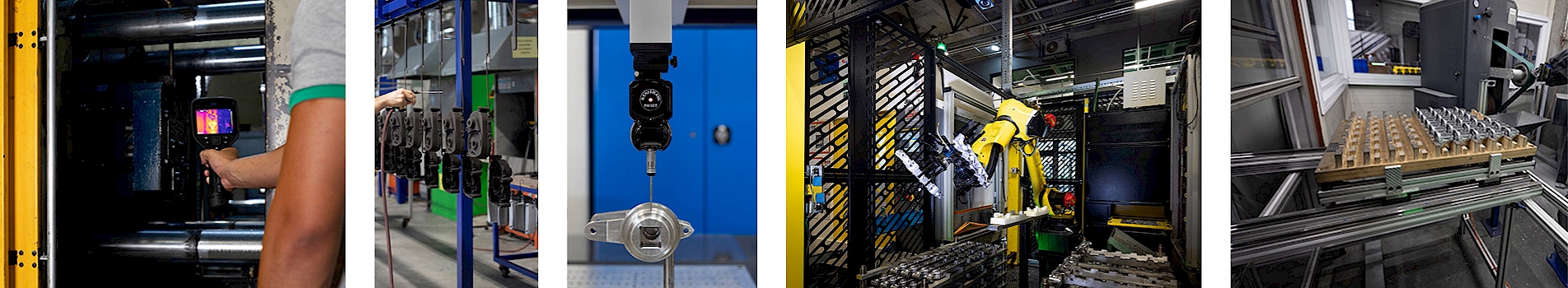

For production and quality control, we employ only the most advanced technologies and processes. Our extensive experience and high degree of in-house manufacturing set us apart as a leading company in the production of aluminum die-cast parts and zinc die-cast parts.

Our company specializes in the manufacturing of aluminum die-cast parts and zinc die-cast parts, complemented by comprehensive mechanical machining capabilities. This proven combination allows us to maximize cost-effectiveness for our customers without compromising on quality. With years of experience and a clear commitment to excellence, we are a trusted partner in the industry.

Our broad range of services includes customized production and precise machining of aluminum die-cast parts and zinc die-cast parts in various dimensions and quantities. Additionally, we offer the option to coat or paint mechanically machined aluminum and zinc die-cast parts according to specific customer requirements. As part of our order processing, we are also pleased to assist in the design or optimization of these components to maximize their benefits or cost-effectiveness. Our skilled designers are available to provide expert guidance.

For production and quality control, we employ only the most advanced technologies and processes. Our extensive experience and high degree of in-house manufacturing set us apart as a leading company in the production of aluminum die-cast parts and zinc die-cast parts.

We also perform additional manufacturing processes such as deburring (tumbling), coating, and heat treatments internally. Leak testing and impregnation are conducted by longstanding and certified partners, ensuring the quality of our aluminum die-cast parts, zinc die-cast parts, and manufacturing processes.

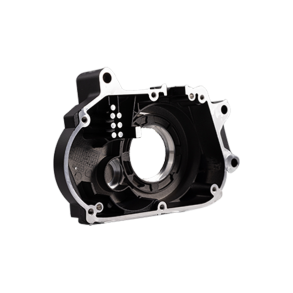

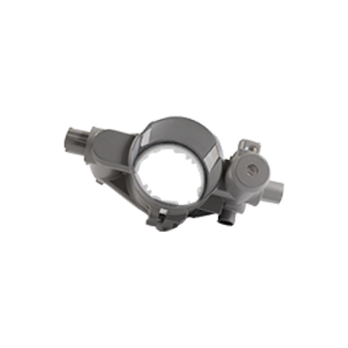

Aluminum die-cast parts and zinc die-cast parts are essential product categories for our company. Our passion for metallurgy and high degree of in-house manufacturing differentiate us from other companies in the die-casting industry. Producing complex and highly precise aluminum die-cast parts and zinc die-cast parts is part of our daily operations. We are your partner when it comes to highest quality at competitive terms.

Aluminum die-cast parts

Maximum tonnage: 15 kg per component

Zinc die-cast parts

Maximum tonnage: 20 kg per component

Revenue Volume

The revenue generated by the sale of die-cast parts by the Alform Group amounts to 11 million euros per year.

Environmental Protection

According to a calculation we conducted, the production of our die-cast parts emits approximately 8% less greenhouse gases compared to regular production facilities in the mechanical engineering sector.