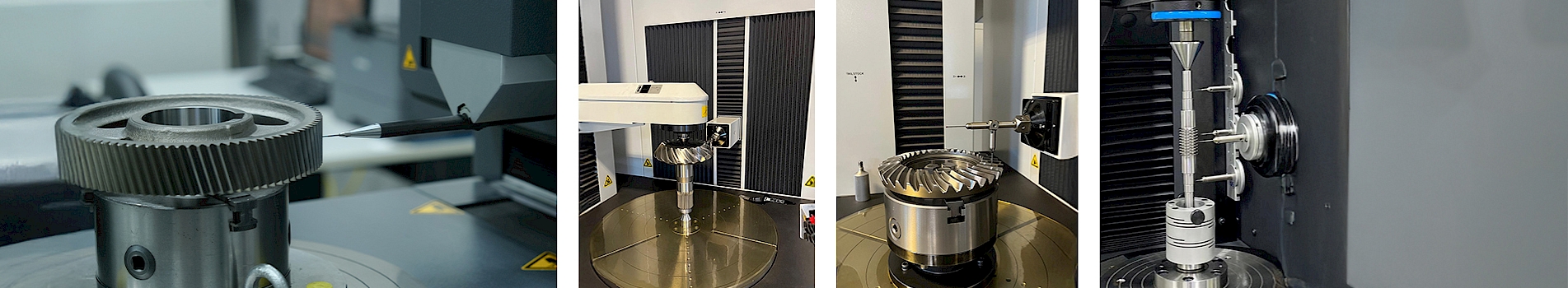

Our gears are used across various industries and companies internationally. Our extensive machinery enables us to manufacture highly complex as well as simpler gearing elements in variable quantities and dimensions at very competitive terms.

Our range of services includes gear design and engineering support for our customers, with our gearing specialists assisting in the design and creation of production drawings. We proactively support the development process of your projects with the aim of offering optimized products and creating cost-saving potentials.

All gears we produce can be ground and measured internally. This capability distinguishes us from alternative companies in the field of gearing technology and provides us with a significant competitive advantage, greatly benefiting our customers.

For over 50 years, we have been producing gears. Our experience sets us apart as a leading company in the field of gearing technology.

We process all common and specific alloys, including plastic alloys, in the form of solid material, cast blanks, and forged blanks. We cast the cast blanks ourselves before machining them, thereby minimizing risk and maximizing cost-effectiveness. With both blanks and finished products coming from the same source, seamless order processing is ensured.

Additional manufacturing processes such as erosion, coating, various heat treatments, and painting are also carried out internally.

We can manufacture all components independently of external parties, setting and executing manufacturing processes according to our internal guidelines to ensure the quality of our gearing elements and manufacturing processes.

Gearing elements are an essential product category for our company. Our gearing elements are used in highly complex constructions and transmissions, demanding reliable and consistent quality. Our passion for precision and detail, coupled with our high level of in-house manufacturing, enables us to meet the demands of our customers. We make the impossible possible, making it our daily mission to realize your requirements and goals.

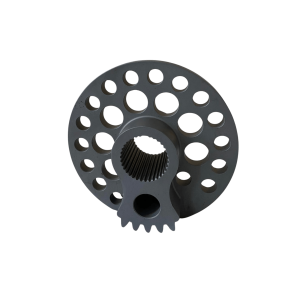

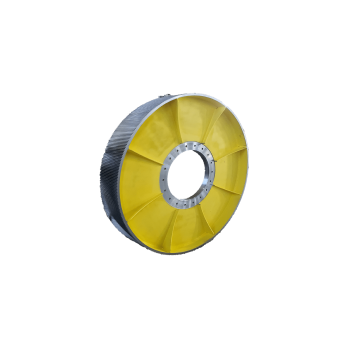

Spur Gear

Straight-toothed / helical-toothed / internal-toothed

Module – maximum: m 90

Outer diameter – maximum: 7,000 mm

Gear quality – maximum: Gear quality 4 according to DIN 3961

Tooth width – maximum: 2,500 mm

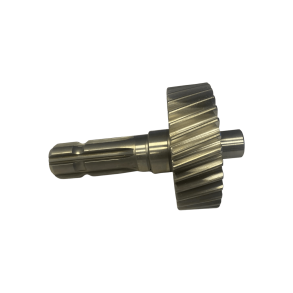

Miller

Pinion Shafts / Keyed Shafts / Gear Shafts

Module – maximum: m 60

Outer diameter – maximum: 3,500 mm

Gear quality – maximum: Gear quality 4 according to DIN 3961

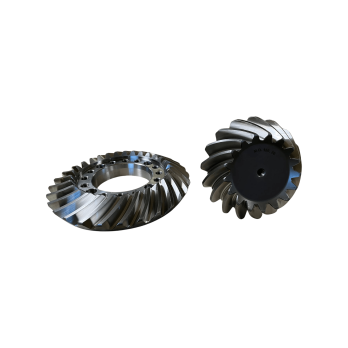

Spiral Bevel Gear Sets

Gleason / Oerlikon / Klingelnberg

Lapped / ground

Outer diameter – maximum: 2,500 mm

Gear quality – maximum: Gear quality 4 according to DIN 3961

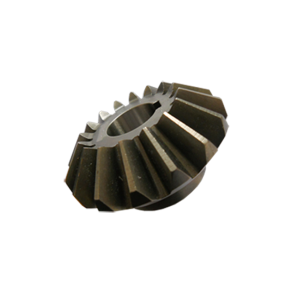

Straight Bevel Gear Sets

Gleason / Oerlikon / Klingelnberg

Lapped / ground

Outer diameter – maximum: 2,000 mm

Gear quality – maximum: Gear quality 4 according to DIN 3961

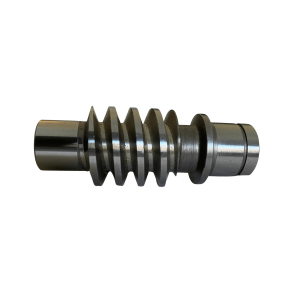

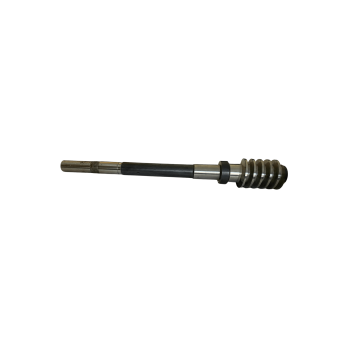

Worm Shafts

Outer diameter – maximum: 1,000 mm

Milled / ground

Gear quality – maximum: Gear quality 4 according to DIN 3961

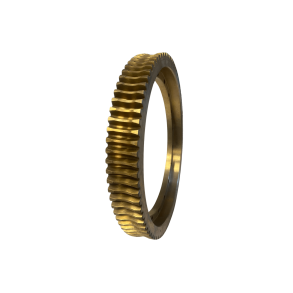

Worm Gears

Outer diameter – maximum: 2,500 mm

Milled / ground

Gear quality – maximum: Gear quality 4 according to DIN 3961

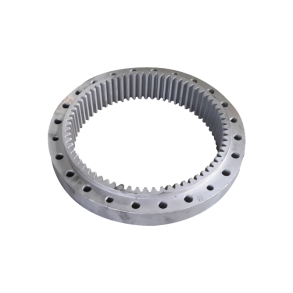

Internal Gear Rims

Module – maximum: m 45

Inner diameter – maximum: 2,500 mm

Milled / ground

Gear quality - maximum: Gear quality 4 according to DIN 3961

Sales volume

The turnover of the Alform Group of companies generated by the sale of gear elements amounts to 28 million euros per annum - about 35% of the total annual turnover.

Environmental protection

According to a calculation that we carried out, in the course of the production of our gear elements, we emit about 17% less greenhouse gases than regular production facilities in the mechanical engineering industry.