Our Alform© couplings are used globally across various industries and companies. Thanks to our extensive machinery and decades of experience, we are capable of manufacturing standard and custom couplings in variable quantities and dimensions extremely cost-effectively.

We offer alternatives to all common and specific Flender, Jaure, and Malmedie couplings, as well as couplings from other manufacturers. Numerous renowned companies in the mechanical engineering sector have been relying on Alform© couplings for years, replacing all installed couplings that need to be replaced with our products. A significant advantage over established competitors in the coupling industry is our ability to deliver equivalent couplings much faster and more cost-effectively than the original manufacturers – with consistent or even, according to customer feedback, sometimes better quality!

Once we receive the model number of the original manufacturer's coupling, we can identify and offer the corresponding equivalent Alform© model. Alternatively, we can manufacture couplings based on drawings, old data sheets, or sample parts.

Our range of services in order processing includes not only the selection of suitable industrial couplings but also comprehensive consulting services. This includes the design and construction of couplings as well as the creation of production drawings. Our specialists are available to ensure your requirements are optimally fulfilled.

For over 50 years, we have been producing industrial couplings and have successfully established ourselves as an alternative to well-known manufacturers due to our cost-effectiveness, flexibility (short lead times), and quality. Our extensive experience makes us a leading company in the field of coupling technology.

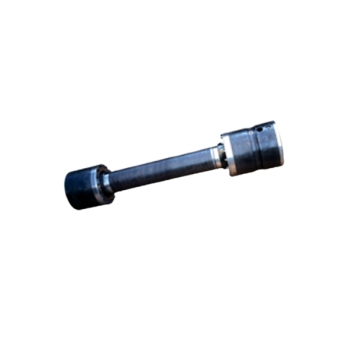

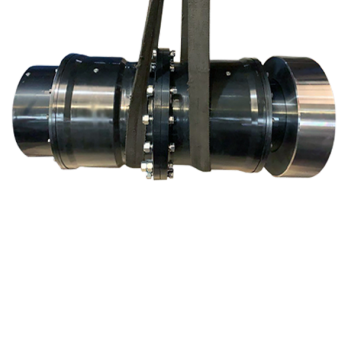

Alform© couplings are particularly reliable, low-maintenance, and incur low investment and operating costs. They also excel as custom solutions with the highest product quality and exceptional lifespan. With various designs, mostly custom-made, we offer a comprehensive range for nearly all applications. We manufacture intermediate pieces for larger shaft distances according to your specifications.

Additional manufacturing processes such as various heat treatments and surface treatments are also carried out internally. We can manufacture all components independently of external parties and define the manufacturing processes according to our internal guidelines to ensure the quality of couplings and manufacturing processes.

Industrial couplings are an essential product category in our company. These are used in highly complex plants and mechanisms, so the quality of our products must always be reliable. Our passion for precision and attention to detail, along with our high manufacturing depth, enable us to meet our customers' requirements. We make the seemingly impossible possible and make it our daily mission to meet your needs and goals. From design to manufacturing, we are here to deliver an optimized, cost-effective, and high-quality industrial coupling.

Torque Range

10 - 10,000,000 Nm

Bore Diameter

Up to 1,020 mm

Types of Couplings

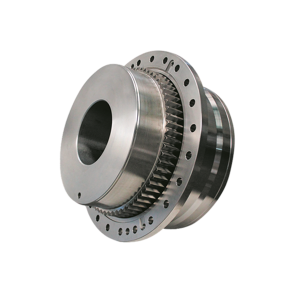

Elastic couplings – pin couplings and all-steel couplings

Gear couplings

Revenue Volume

The revenue generated by the sale of Alform© couplings by the Alform Group amounts to 8 million euros per year.

Environmental Protection

According to a calculation we conducted, the production of our industrial couplings emits approximately 14% less greenhouse gases compared to regular production facilities in the mechanical engineering sector.