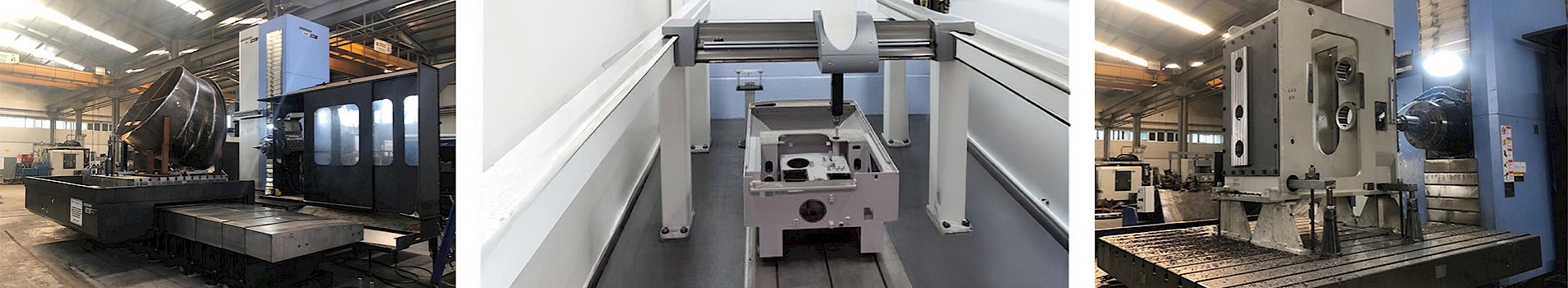

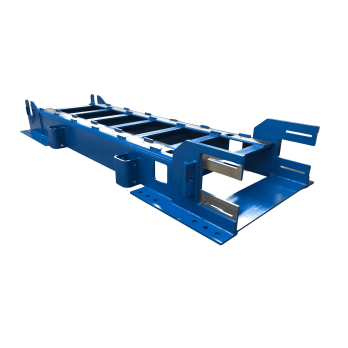

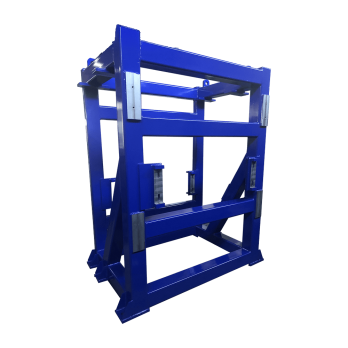

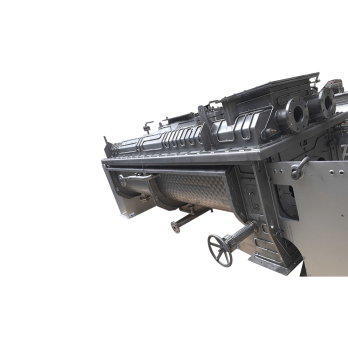

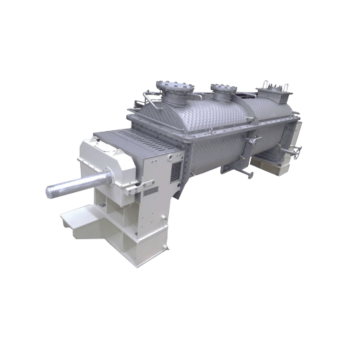

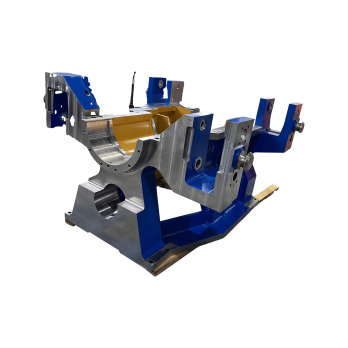

Our welded assemblies and container constructions are used internationally in various industries and companies. Our extensive machinery allows us to manufacture both the most complex and simple welded assemblies, in variable quantities and dimensions, at very economical conditions.

Dimensions - Specifications

Welded Assemblies

Mechanical Processing

X-axis - maximum: 30,000 mm

Y-axis - maximum: 13,000 mm

Z-axis - maximum: 4,000 mm

Certificates and Approvals

- EN ISO 3834-2

- PED 2014/68/EU

- ATEX 94/9/EC

- ISO 9001

- TÜV CERTIFIED

PDF data sheet for download:

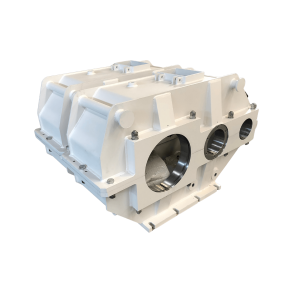

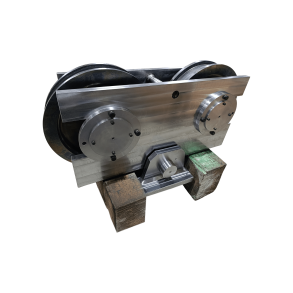

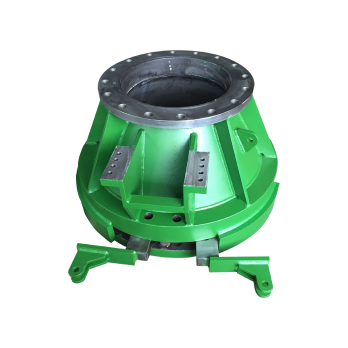

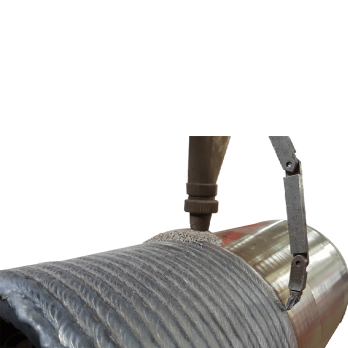

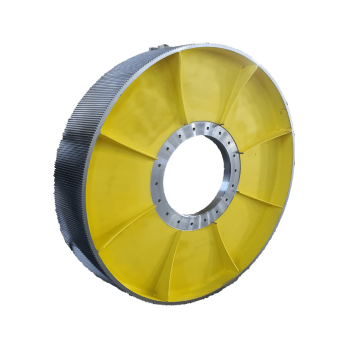

Our project scope in the field of welded assemblies is highly diverse, ranging from the production of a simple gearbox housing to the manufacturing of welded assemblies and welding components for a fully integrated system. Our core competence lies in our many years of experience—producing highly complex welded assemblies is part of our daily work.

To optimize the technical properties of your designs and identify potential savings, our engineers support you—if required—in the planning and design of your welded structures. We accompany you from the project design phase to completion and assembly. Our assembly team, consisting of certified welding specialists, carries out the assembly of our welded assemblies internationally.

We weld all common as well as more specific alloys. Additional manufacturing processes such as coating, sandblasting, various heat treatments, and painting are also carried out in-house. All welded assemblies we produce can be manufactured independently of external parties. We define the manufacturing processes ourselves and perform them according to our internal guidelines, which enables us to ensure the quality of both our welded assemblies and the manufacturing processes we carry out.

We manufacture in accordance with EN, ASME, GOST, and SASO standards, as well as the construction directive PED2014/68/EU-EC. The corresponding documentation, including the CE mark and ASME U & S stamp, is also provided by us.

Welded assemblies represent an essential product category of our company. Our welded assemblies are used in highly complex constructions and systems, which is why the quality of our components must always be reliably ensured. Our passion for precision and detail, along with our high level of in-house manufacturing, enables us to meet our customers’ requirements. We bring your ideas and visions to life—from design to assembly!

Revenue Volume

The revenue generated by the sale of welded assemblies by the Alform Group amounts to 11 million euros per year – approximately 13.75% of the total annual revenue.

Environmental Protection

According to a calculation we conducted, the production of our welded assemblies emits approximately 11% less greenhouse gases compared to regular production facilities in the mechanical engineering sector.