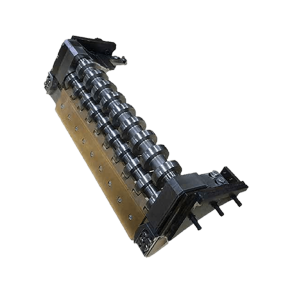

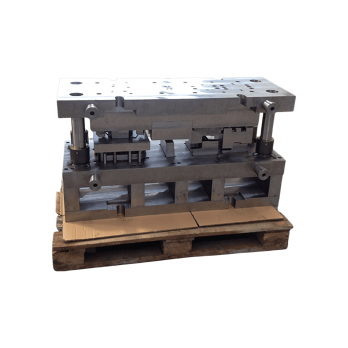

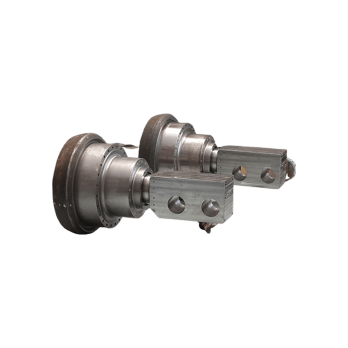

We produce CNC turned and milled parts for various industries and companies worldwide. Our extensive machinery allows us to manufacture both the most complex and simple CNC turned and milled parts in variable quantities and dimensions at very economical prices.

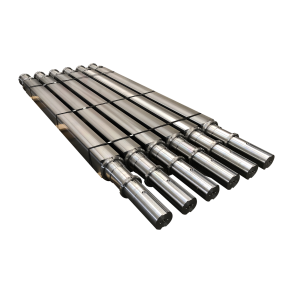

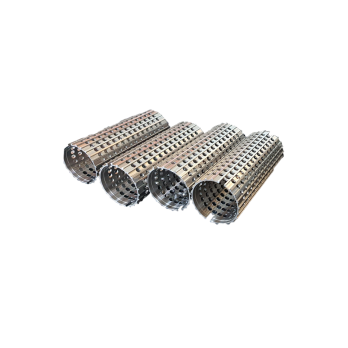

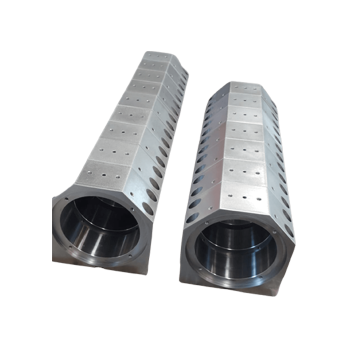

CNC Turned Parts

Maximum diameter: 7,000 mm

Maximum length: 25,000 mm

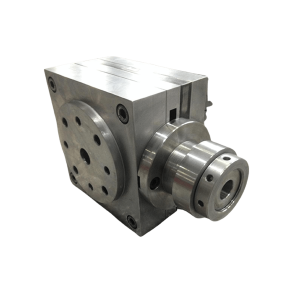

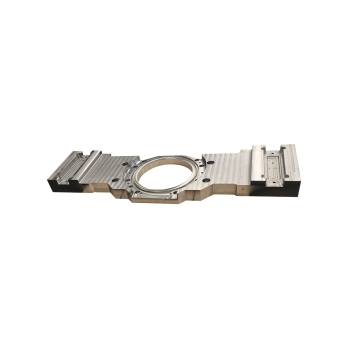

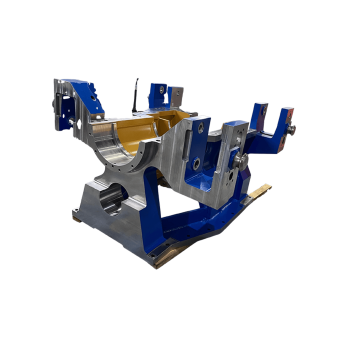

CNC Milled Parts

X-axis - maximum: 30,000 mm

Y-axis - maximum: 13,000 mm

Z-axis - maximum: 4,000 mm

PDF data sheet for download:

For the production and quality control of our components, we exclusively employ state-of-the-art technologies and processes. Our expertise, derived from years of experience, and our high degree of in-house manufacturing capabilities make us one of the leading companies in the field of machining technology.

We process all common and specific alloys in the form of solid materials, cast blanks, and forged blanks. We cast the cast blanks ourselves and subsequently machine them, thereby minimizing risk and maximizing cost-effectiveness. Raw materials and finished products originate from the same source, ensuring smooth order processing.

Additional manufacturing processes such as EDM machining, grinding, coating, various heat treatments, and painting are also carried out internally. We are fully capable of producing all components independently of external parties. We establish and execute manufacturing processes according to our internal guidelines, ensuring the quality of our CNC turned and milled parts and the processes we implement.

CNC turned parts and CNC milled parts are essential product categories in our company. Our commitment to precision and detail sets us apart from alternative manufacturers in the machine engineering industry, where the production of complex and high-precision CNC turned and milled parts is integral to our daily operations. We aim to achieve every technically feasible tolerance.

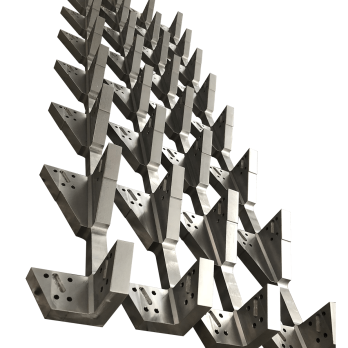

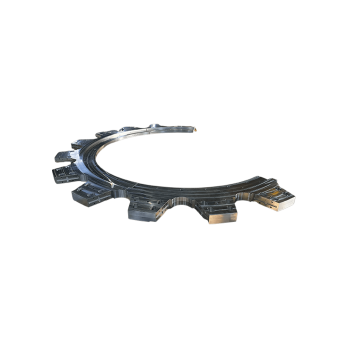

Sales Volume

The Alform Group's annual sales generated by selling gear elements amount to €28 million - approximately 35% of total annual sales.

Environmental Protection

According to a calculation we conducted, we emit approximately 17% fewer greenhouse gases during the production of our gear elements than regular production facilities in the mechanical engineering industry.